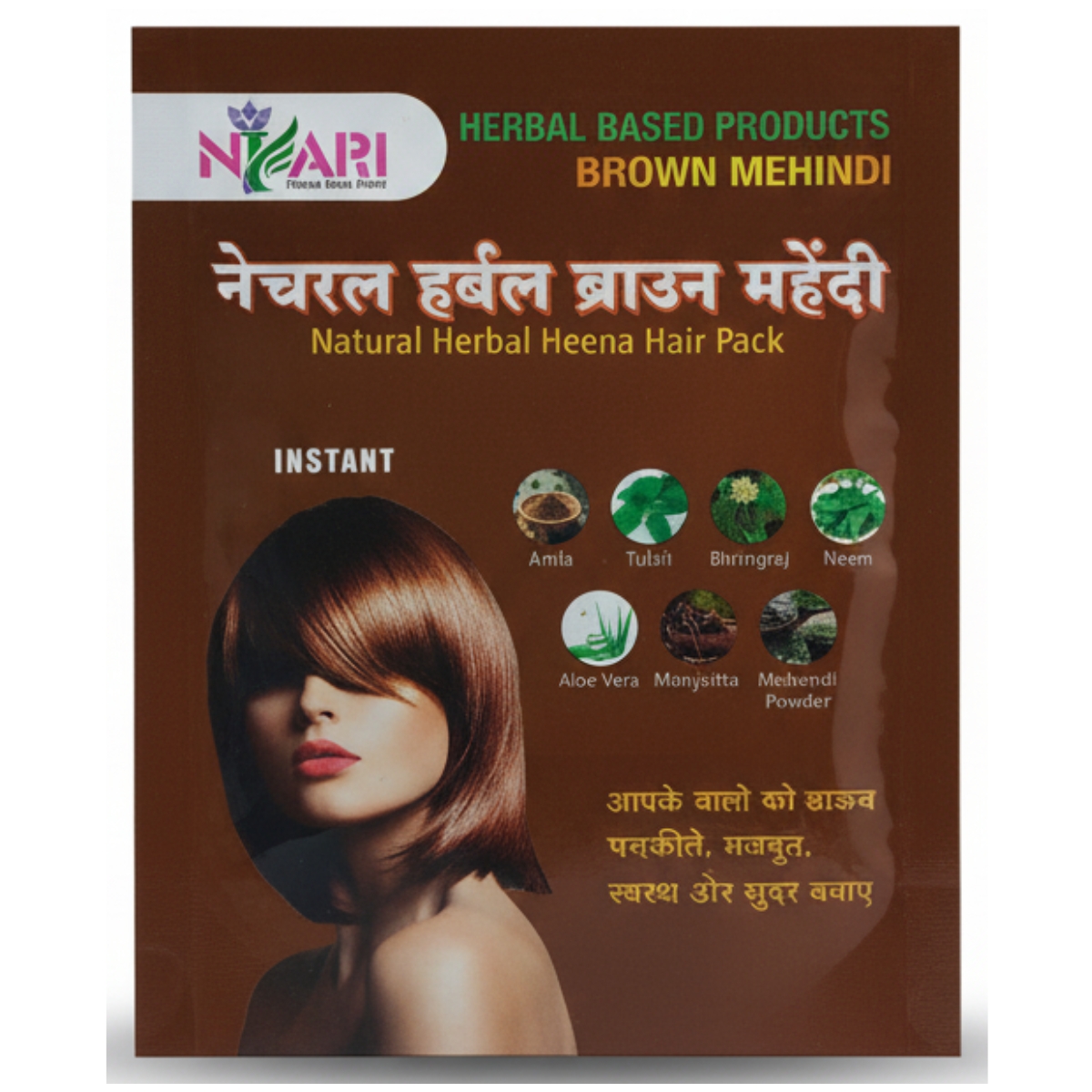

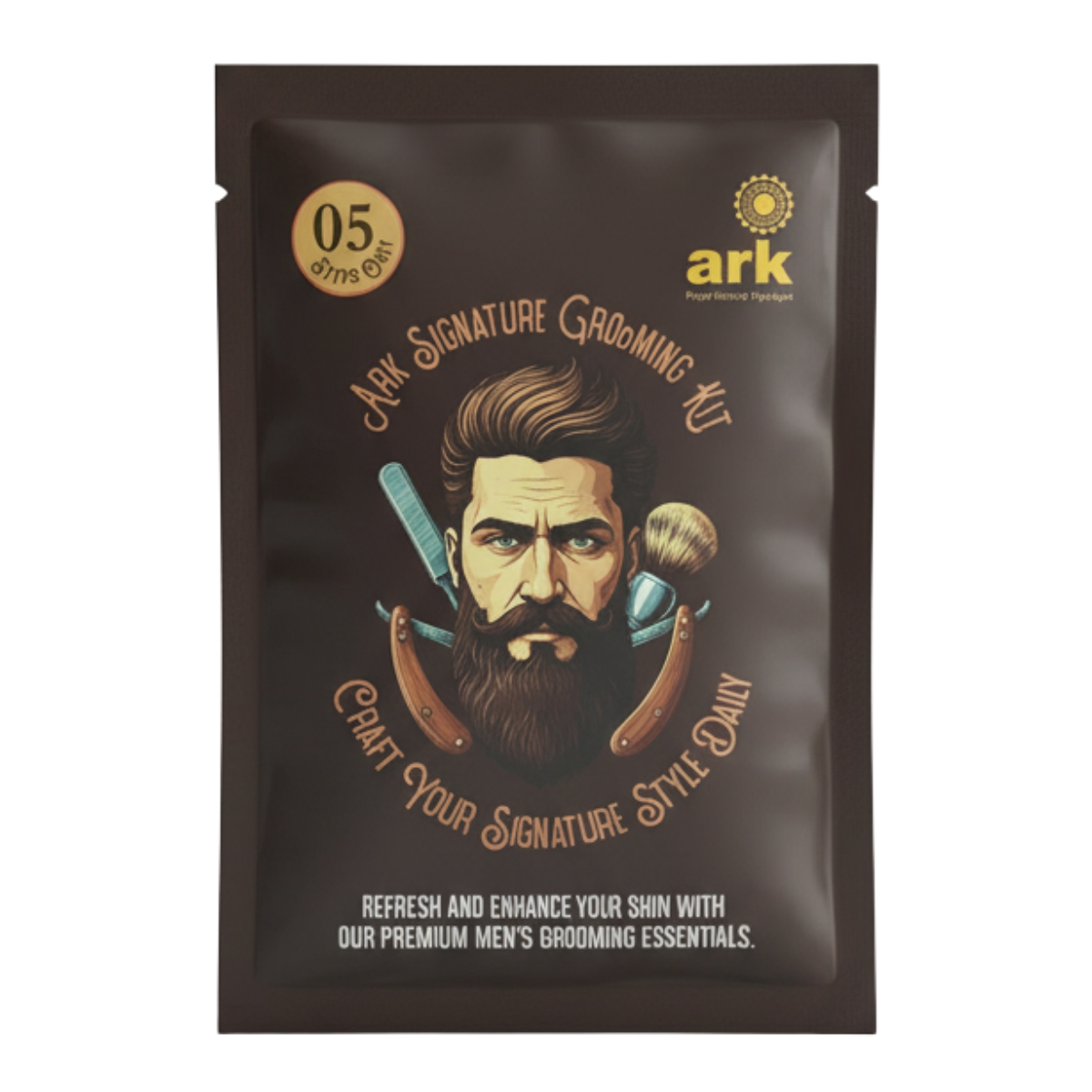

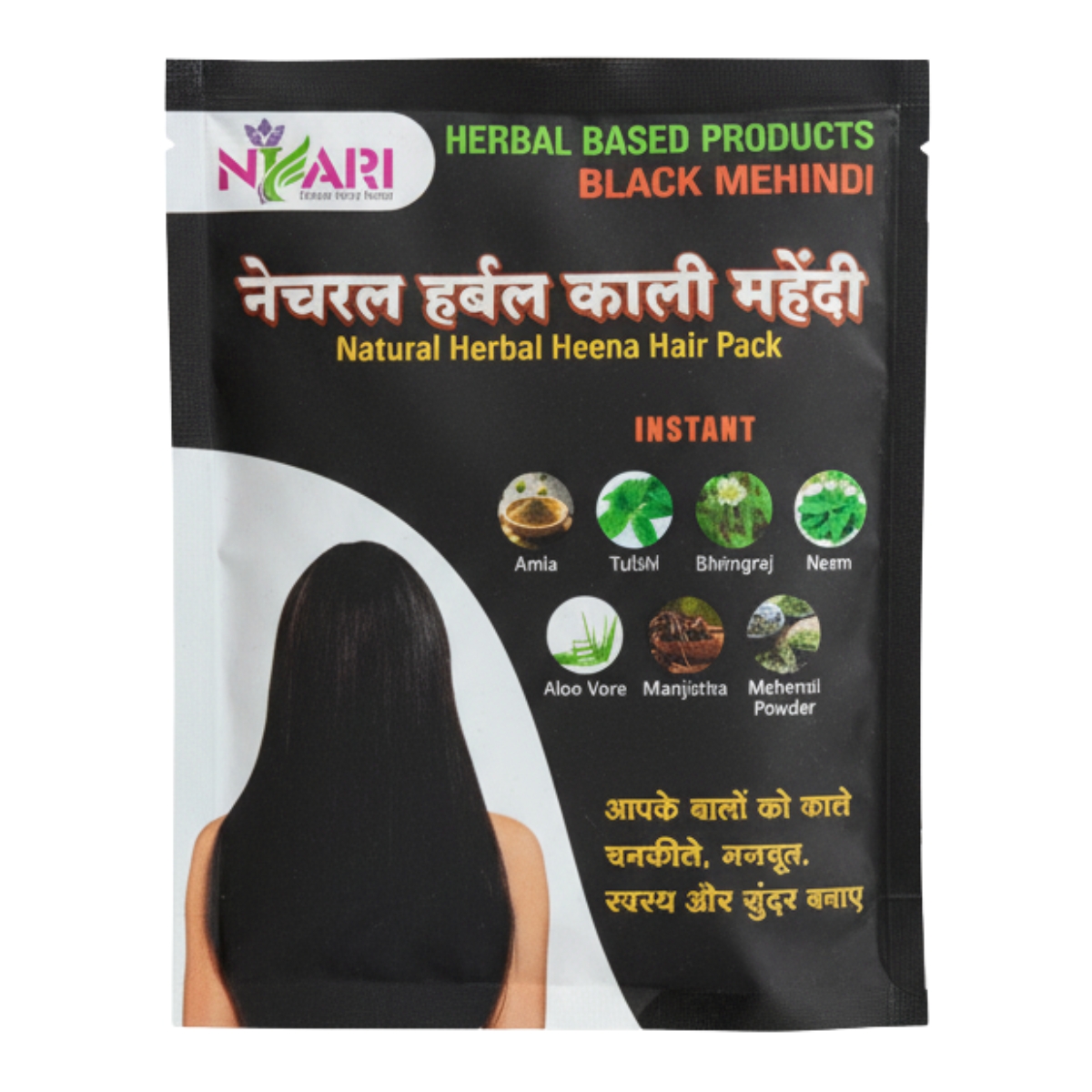

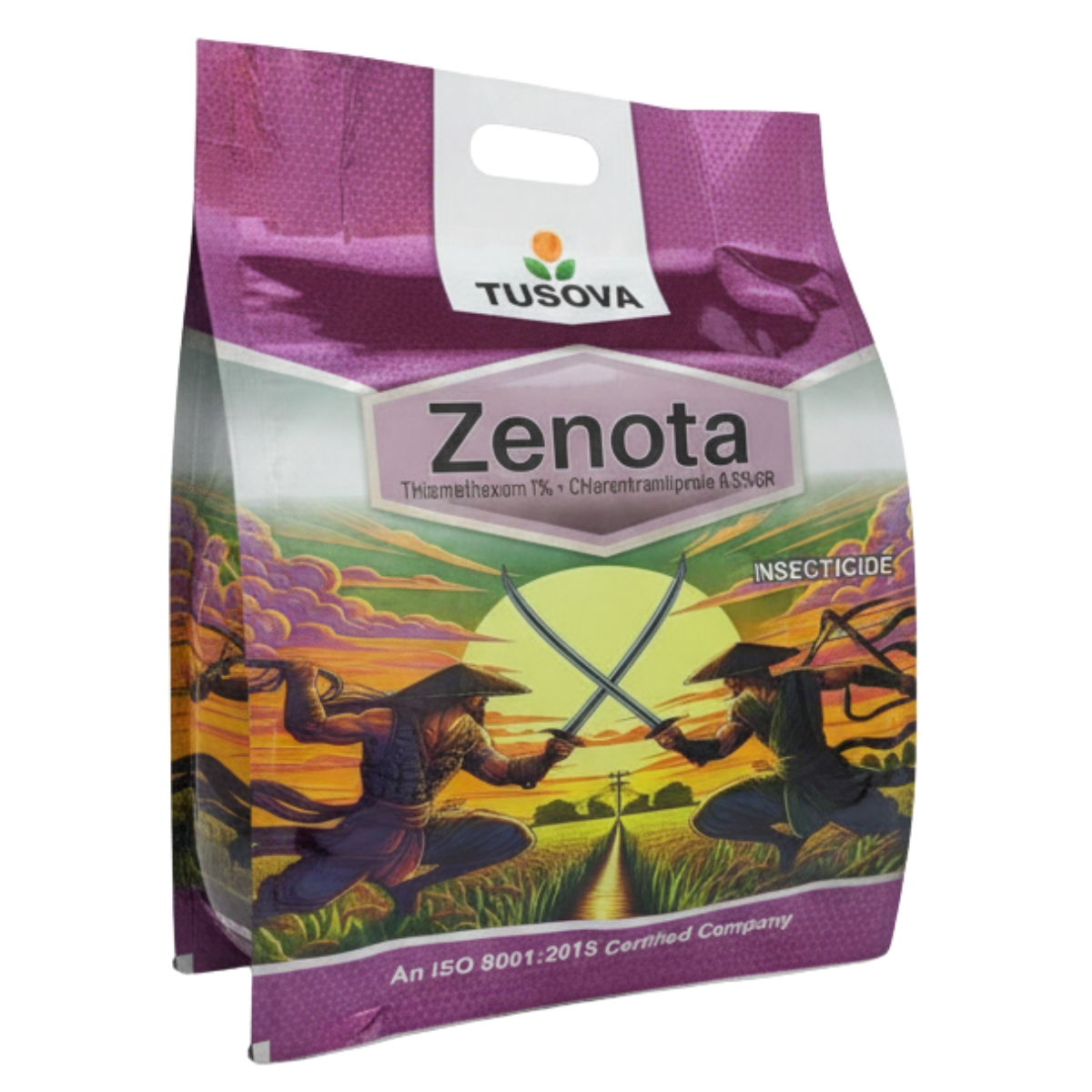

Types of Pouches We Print

We provide high‑quality printing for all major pouch styles used across FMCG, food, cosmetics, home care and premium retail packaging.

3 side seal pouch ~Centre seal pouch ~Standy Zipper pouch ~Gusset pouch ~Window Pouch ~Transparent pouch ~Matte finish pouch ~Metallic pouch Fast, flexible pouch printing with or without cylinders

Pouch Printing

At National Print we offer high-quality pouch printing tailored for every need — from short, custom batches to large-scale production. Choose Cylinder-less (fast & flexible) or Cylinder-based (best for long runs & special finishes) printing depending on your budget, timeline and finish requirements.

Cylinder-less Pouch Printing

(No Cylinder)

- Best for: short to medium runs, rapid turnaround, variable data, frequent design changes and prototypes. What it is (simple): Cylinder-less printing uses modern digital/CI-less technologies that print directly onto film or a printing plate without the need for metal cylinders. That means faster setup and lower up-front costs.

- Benefits: Zero cylinder costs — no tooling fees, ideal for small batches. Quick turnaround — faster setup and production. Easy revisions — change artwork between batches without extra cost. Variable data & customisation — serial numbers, batch codes, QR codes or personalised designs printed per pouch. Lower inventory risk — print on demand to reduce storage costs.

- Typical runs: 100 — 50,000 pouches (depends on design and material). Suitable applications: start-ups, seasonal products, limited editions, trial packs, private labels, market testing.

- Product focused considerations to ensure safety and easy user function for your customers

- Material & finishing options: Films: PET, CPP, PA, laminates, biodegradable films (subject to availability) Finishes: matte, gloss, satin, gloss/matte lamination Functional options: zipper, spout, tear notch, gusset, resealable options

- Artwork requirements: PDF/X or high-resolution PDF with fonts embedded CMYK (and spot colours if required) at 300 DPI Include bleed: 3–5 mm For variable data: provide a clear CSV template and sample artwork

Cylinder Pouch Printing

(With Cylinder)

- Best for: medium to long runs, repeat orders, premium brand packaging, colour-critical designs and high-volume production. What it is (simple): Cylinder pouch printing uses engraved metal cylinders to transfer ink onto packaging films through rotogravure or CI flexographic printing. Each colour requires its own cylinder, allowing ink to be applied with exceptional accuracy and consistency. This method is ideal for brands that require reliable repeatability and high-end visual quality across large production volumes.

- Benefits: Cylinder printing delivers outstanding print clarity, smooth gradients and excellent ink density, making it suitable for retail-ready and export packaging. Once cylinders are produced, unit costs reduce significantly for larger quantities. It ensures consistent colour matching across multiple production runs and provides dependable results for long-term product lines. This method is highly stable and efficient for continuous, large-scale manufacturing.

- Typical runs: Typically suited for runs starting from approximately 25,000 pouches and extending into hundreds of thousands or millions, depending on pouch size, material structure and number of colours.

- Suitable applications: Well-established brands, mass-market consumer goods, supermarket and retail packaging, export products, and SKUs with fixed artwork that require long-term production continuity.

- Product focused considerations to ensure safety and easy user function for your customers: Cylinder printing supports a wide range of high-barrier and food-safe materials, ensuring product protection and shelf life. Precision registration allows accurate placement of functional features such as zippers, tear notches and spouts, ensuring reliable opening, resealing and overall consumer usability.

- Material & finishing options: Compatible materials include PET, BOPP, CPP, PA, aluminium foil laminates and other high-barrier structures. Finishing options include gloss, matte, satin and registered matte/gloss effects. Functional enhancements such as resealable zippers, spouts, gussets, euro holes and tear notches can be incorporated based on product requirements.

- Artwork requirements: Finalised artwork is required prior to cylinder engraving, as any changes after approval may result in additional tooling costs. Artwork should be supplied as PDF/X or high-resolution PDF with embedded fonts, prepared in CMYK with spot colours where required at a minimum resolution of 300 DPI. A bleed allowance of 3 to 5 mm should be included, and trapping and overprint settings must be confirmed before final approval.